Stories

Ambitious goals call for big ideas and the brightest minds. Get to know the passionate, dedicated people behind Pathways Alliance.

Inspiring the future: Commitment to education

Pathways Alliance empowers Canadian startups at CERAWeek

Agreements continue valuable oil sands research at the University of Alberta

Stories

54 stories shown

Inspiring the future: Commitment to education

Pathways Alliance empowers Canadian startups at CERAWeek

Agreements continue valuable oil sands research at the University of Alberta

Toads with backpacks: what’s going on?

Energy security is the world’s biggest problem and we are helping by supporting the transition to cleaner energy.

Ariel Torre, Co-founder and CEO, Impossible Sensing Canada

Pathways Alliance holds community information sessions on proposed carbon capture network

“We are the ones who have to deliver”

Artificial intelligence helping to drive down emissions in oil sands facilities

Pathways Alliance helps start-ups access funding

The tremendous response to this challenge demonstrates the level of partnership the oil sands industry has with leading innovators around the world.

Wes Jickling

Vice President, Technology Development, Pathways Alliance

Industry innovation begins in the classroom

eDNA is revolutionizing biodiversity monitoring in the oil sands

24th World Petroleum Congress 2023

Investigating what’s natural and what’s not

Climate change is a critical challenge, and the oil sands industry has an essential role to play in reducing emissions. Our path to net zero will help our country achieve a sustainable future.

KENDALL DILLING, PRESIDENT, PATHWAYS ALLIANCE

Pathways Alliance techno-assessment process showing some “cool” results

Using the light spectrum to see into tailings

Innovation Hacks: Helping innovators access private funding

Bugs Help Vegetation Grow on Tailings

Emerging Technologies: Natural gas decarbonization

Innovation Hacks: Industry searches the world for solutions to sustainable development

Outdoor trials test water treatment innovation

Canada’s Boreal Forest: Six fast facts to know

Pioneering Reclamation at Lake Miwasin

Water Management 101: Using water wisely

Wetland 101: What is a wetland?

Experience, enthusiasm has Pathways Alliance team focused on solving the net zero emissions puzzle

What do you need to know about pit lakes?

Oil Sands Monitoring Program 101

Emerging Technologies – Steam reduction technologies

Students’ engagement with industry inspires next generation

Reducing Waste

Pathways Alliance committed to Earth Day theme to “Invest in our planet”

Monitoring Habitat

Treating Tailings

What Does It Take For New Forests To Grow?

Emerging Technologies: New Water Treatment Technologies Address Emissions

Creating Wetlands

Oil sands sector gaining global recognition as a long-term secure supplier in a net zero world

Emerging Technologies: Cutting edge water treatment technologies

Shafak Sajid’s passion for policy wins her a 2022 YWE award

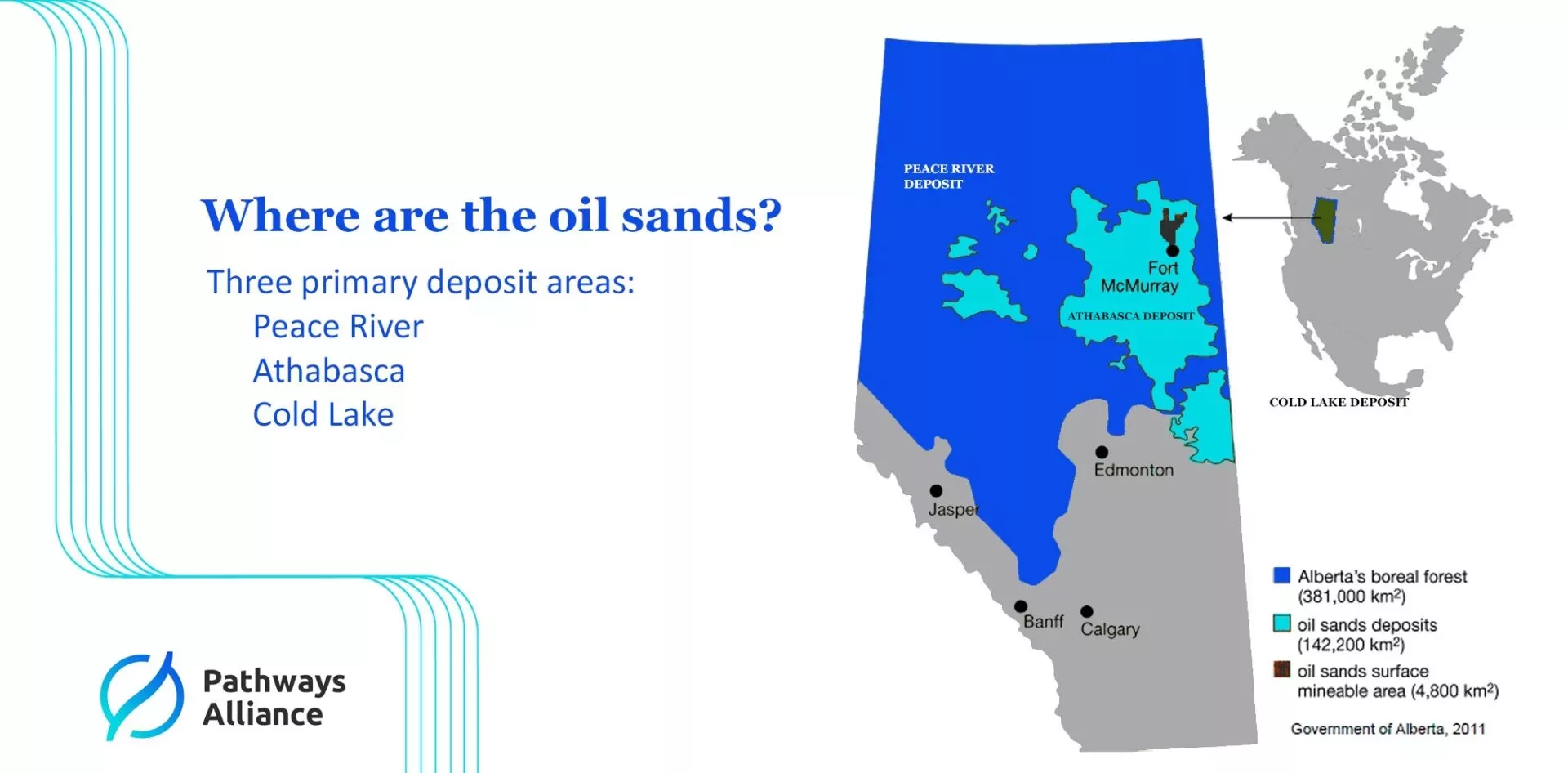

Oil Sands 101: What’s different about Alberta’s oil sands

Restoring Caribou Habitat

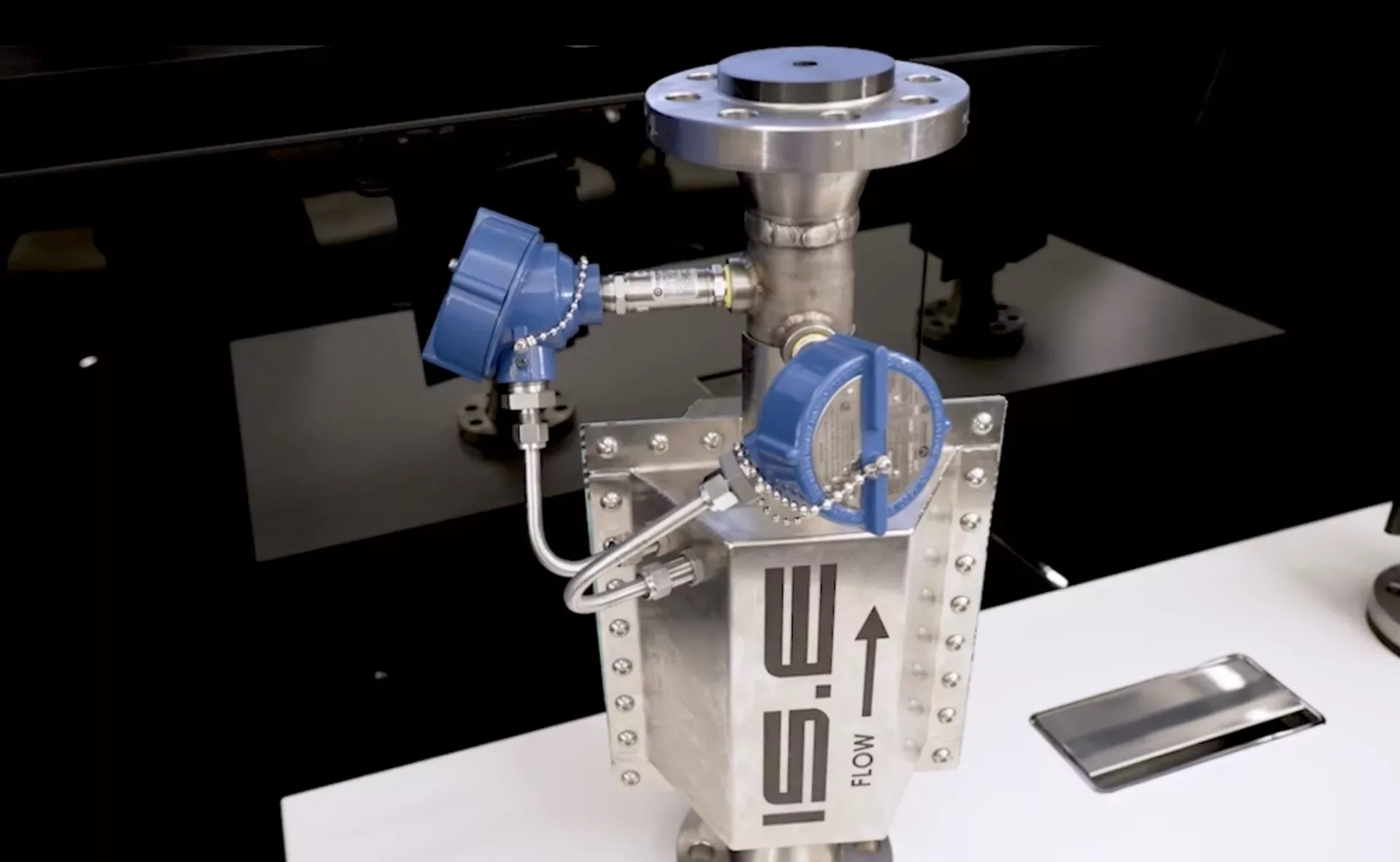

Emerging Technologies: Fugitive Emissions

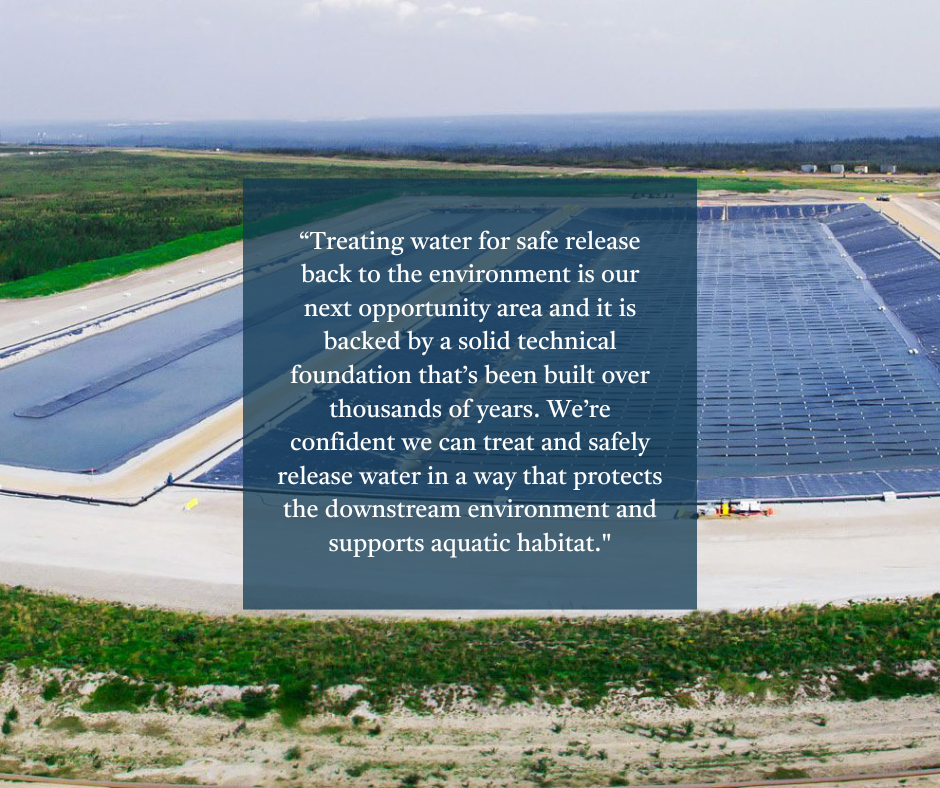

Water treatment: An opportunity for today

Thinking small can solve big industry challenges

Water release proposal supported by strong science

How will industry manage and reduce risk on its proposed CCS network?

Emerging Technologies: Molten Carbonate Fuel Cells

From Mars to McMurray: Industry scours the world – and beyond – in a quest to reduce emissions

Emerging Technologies: Advancing geothermal energy for mining

Arlene Strom’s passion for the energy transition drives her work

Emerging technologies: Decarbonization

Emerging Technologies: Mining Electrification

Modest beginnings help Pathways Alliance president with grand goals toward net zero

Blog: Pathways’ leaders inspire women in climate challenge